Home Blog Product Info What Are EMVs and How Do They Work?

Excavator Mounted Vibrators (EMVs) have an incredible strength-to-weight ratio, making them the perfect tool for readily converting any suitable size excavator into a highly productive pile-driving machine.

In this blog post, you will learn everything you need to know about EMVs, including what they are, how they work, and their features and benefits.

What Is an EMV?

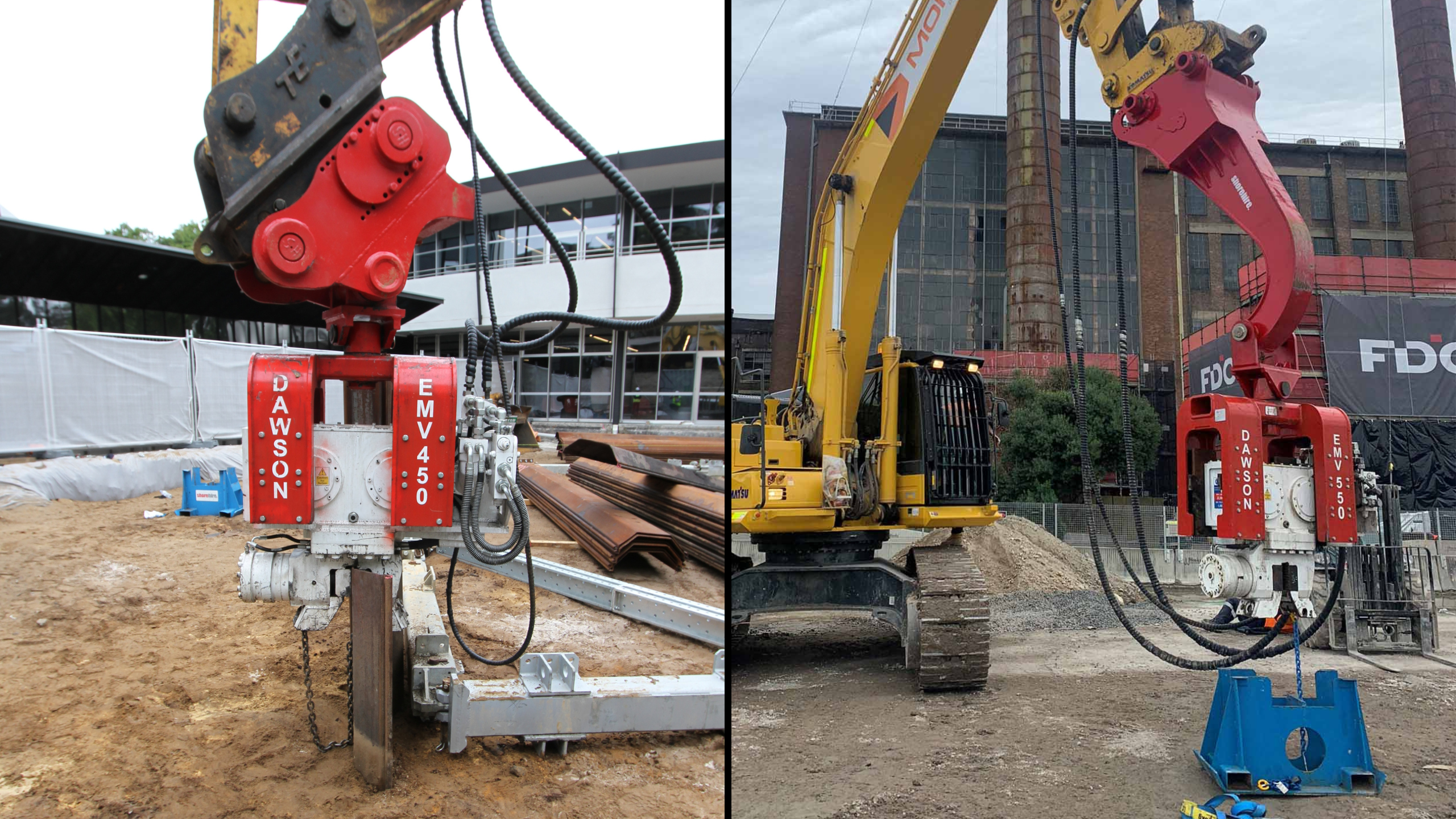

EMVs attach directly to an excavator and are specifically designed to help safely drive and extract Trench Sheets and Sheet Piles by hydraulically vibrating the equipment into and out of place. When an EMV is installed on an excavator, it can drive and extract Trench Sheets, Sheet Piles, H Beams, and casings for shoring for all types of trenches, bore pits, pump stations, and other types of excavations.

United Rentals has three sizes of EMVs available:

- The EMV300, which requires a 12 – 35 tonne excavator

- The EMV450, which requires a 25 – 45 tonne excavator

- The EMV550, which requires a 30 – 55 tonne excavator

We also have two accessories available with our EMVs, our Quick Hitch Adaptor Brackets and Swan Neck Attachments. Quick Hitch Adaptor Brackets allow an excavator to release the excavator bucket and effortlessly connect to the hitch which is pre-assembled onto the EMV. This allows the excavator to quickly change between attachments when carrying out a dual role.

A Swan Neck Attachment allows for an extended reach and greater sheet clearance on an excavator’s arm, enabling longer Trench Sheets and Sheet Piles to be driven from further away. The added reach from the Swan Neck Attachment means a more accessible and efficient installation that dramatically reduces the risk of damaging equipment. It also means the operator can work further away from the edge of the excavation for an even safer installation.

How Does an EMV Work?

Trench Sheets or Sheet Piles can be lifted into a vertical position using our lifting chains, where they are then gripped tightly in a powerful hydraulic jaw.

Once secured, the sheets are then vibrated with high-frequency vibrations so as to ‘fluidise’ the soil resisting the sheets. The fluidising effect on the soil permits particles to shuffle themselves around, creating some spaces for the Trench Sheet or Sheet Pile to move into. This, combined with the weight of the pile and vibrator is adequate to push the sheets into the ground.

To ensure safe and effective use, Excavated Mounted Vibrators should always be operated in accordance with the manufacturer’s operating instructions.

What Are the Features and Benefits of EMVs?

The main advantages of EMVs are their small size and the ability to be easily mounted directly onto excavators without the need to hire and mobilise expensive piling plant. This improves their workability in small spaces, while also having a minimum effect on the environment and surrounding structures and reducing noise pollution.

With an incredible power-to-weight ratio and a slim design, our compact, robust, and reliable EMVs can be attached directly to an excavator boom or via a range of quick hitch adaptor brackets suitable for any machine. The EMVs reduce the cohesion and friction of soils through vibrations, effectively fluidising the soil. This makes it easier and more cost-efficient to install Trench Sheets and Sheet Piles than other traditional installation methods.

When you hire one of our EMVs, you can be sure you’re getting the highest standard of gear – every EMV, Swan Neck Attachment, and Quick Hitch Adaptor undergoes a thorough Return Inspection Procedure (RIP). This procedure checks all critical parts, including welds, steel, shear pins, sleeves, stiffeners, elastomers, and bosses for any signs of impact damage, warping, splits, and overall condition.

If you would like to find out more about our EMVs, or any of our other shoring products and solutions, get in touch with our expert team today.