Home Blog Product Info Everything You Need to Know About Propping

In the construction industry, temporary propping is required for a huge number of projects, and is often a defining factor as to whether the project is successful or not.

In this comprehensive guide, you will learn all you need to know about temporary propping, including when it is required, the different types of props that can be used, how it is installed, how to determine how many props are needed for a project, and much more.

What is propping in construction?

Temporary propping, also referred to as building props or temporary propping systems, involves installing a system of structural supports to support the load of an existing or new structure, therefore allowing construction work to be done to the structure itself, or nearby.

when is propping required in construction projects?

While props are needed on almost every construction project, they are indispensable when there is a risk to the stability of a structure, like if the load-bearing capacity is compromised or set to be removed.

Construction props might also be necessary if:

- There are cracks in a structure’s walls, floor, or ceiling. This can be structural damage and indicates that the structure’s load-bearing capacity has been compromised.

- A load-bearing wall, beam, or column is going to be removed during construction or renovations. This changes the load of the structure and means that it will be unstable unless it is supported by props.

- A roof is going to be repaired or replaced. Construction props will support the roof’s weight and prevent it from collapsing as work is done to it.

- A foundation is being underpinned to increase its load-bearing capacity. In order to make sure the foundation is supported while it’s being underpinned, props need to be used.

- A structure is going to be demolished, construction props can be used to support adjacent structures.

- A new structure is being developed, which will require support while it’s being constructed or ‘setting’ such as formwork propping.

If you are unsure whether to use construction props, it is best to consult a professional engineer or builder, because they will be able to assess the structure and determine if props are necessary to ensure the stability and safety of the structure during the construction or renovation process.

Shore Hire offers an end-end engineering, equipment hire and installation service for all sorts of propping applications.

WHAT IS A prop?

Construction props are temporary supports that are usually tubular or rectangular and made from either aluminium or steel. Props are often height-adjustable and telescopic or modular, meaning that they can be used in various propping applications and construction environments.

what are the most common type of props?

- Titan Props: Titan Props are an incredibly popular temporary propping solution because they are made from a lightweight material, are man-handleable, and have a Working Load Limit (WLL) of more than 13 tonnes. They are designed to support vertically applied stable loads and come in four different sizes, each with its own range of extension sections.

- Acrow Props: Acrow Props are easily the most popular prop in the construction industry, and it’s not hard to see why. They are economical, incredibly lightweight, easy to transport, and easy to erect. Acrow props are modular and height-adjustable, consisting of an outer tube with a solid base and an inner tube with a solid top plate.

- Strong Boys: Strong Boys are an accessory product usually used on top of acrow props, they are robust steel attachments designed to support masonry walls whilst lintels or beams are installed. They are a simple, highly practical underpinning solution that fits onto the top plate of Acrow props and contains an easily hammerable blade designed for use in mortar joints.

- Needle Beams: Needle Beams are load-bearing beams that are used in tandem with our other propping systems for needling applications. Needle beams are penetrated through a structure and then onto whatever temporary propping system is used on either side to create a goal post-type setup. Shore Hire’s Needle Beams are reinforced with additional stiffener plates and galvanised for extra strength and protection.

- Power Pole Support: Another product In Shore Hire’s extensive propping range is a Power Pole Bracket, a custom-built solution designed for pole propping applications. A steel clamp is used instead of a more costly and bigger system like a Pole Grab Truck and is able to be used on a wide range of common poles. The system can be used with our range of Tilt and Modular Raking Props which can then connect to our Engineered Block on the ground to ensure a fully safe and compliant system.

- Tilt Props (Aluminium and Steel): Shore Hire supplies Aluminium and Steel Tilt Props, sometimes referred to as ‘push-pull props’, in a variety of lengths and load-bearing capacities. Adjustable by extension and with fine alterations possible by an ACME thread design, their high strength-to-weight ratio allows safe and accurate installation. They are often used to brace concrete walls or vertical structures during construction, where the tilt-up technique is used during materials assembly.

- Modular Props (Shore 100, Shore 400, and Shore 1000): Shore Hire’s Modular Props provide customers with the ultimate combination of load-bearing and flexibility. The Shore 100, Shore 400, and Shore 1000 are part of Shore Hire’s modular propping offering – all of these products are designed to be used in horizontal and vertical applications, as well as back propping, falsework, facade retention, support towers, underpinning, demolition support, and raking. They truly are the most flexible propping solution available and allow for a much larger range of propping applications to be completed than more common building props would.

- Multi Props: Multi Props are a great temporary propping solution for a variety of construction applications because they are low weight, but have a high load capacity. They are an optimal system for shoring slab work of almost any thickness and weight, and when arranged in a tower of four, they are able to handle even greater loads.

- Trishores: Trishore Props are designed to support heavy vertical loads at considerable heights. They are a modular temporary propping system ideal for heavy-duty propping and underpinning in a range of construction environments. Trishores can support exceptionally heavy and concentrated loads, such as multiple suspended floors in high-rise structures or bridge applications, when positioned or braced in groups.

Not sure which propping system is right for you? Try Shore Hire’s state-of-the-art prop selector tool, and we’ll recommend you the best prop for your job.

WHAT ARE some other common propping applications?

Temporary Propping includes a variety of applications, including:

- Retaining Walls: Propping a retaining wall involves running raking props from the wall down to a solid concrete footing. Depending on the height and type of retaining wall, the type of prop and the position it will be installed in will differ. For example a 2 meter tall single brick wall will have a very different propping setup to a 5 meter tall concrete panel.

- Back Propping: Back propping refers to installing vertical bracing to spread force down to a solid base, such as a concrete slab. It’s incredibly important that when back propping a structure, there must be a solid base of concrete or timber sleepers and either concrete or some sort of beam above the props being used for back propping. We recently launched our Prop Selector Tool, which can help determine which prop to use for a back-propping application.

- Façade Retention: Façade retention refers to propping that is done to protect the facade of a building (often a heritage-listed one) while construction work is done on other parts of the property. Façade retention applications are often very unique and require bespoke solutions where multiple types of props are used.

- Uplift Reduction: Uplift reduction refers to propping that is used to stop a structure from lifting off the ground (like an open-air shed or awning), or from the top of another structure (like a roof). By transferring the load from where there is potential uplift down to the ground, in, for example, an open-air shed or awning, you reduce the chance of uplift, protect the structure, and minimise the danger for others.

- Push/Pull or Tilt Bracing for Pre-Cast Panels: Pre-cast concrete panels are made by casting a reusable mould, and then lifted into place. It’s likely that when panels are placed, they need to be propped, and this will be done using tilt or push/pull props. Propping designs for pre-cast panels are necessary to account for wind loading while they are set in place.

- Formwork Applications: Formwork is the surface of the form that concrete is poured into. While the concrete is setting, the formwork needs to be propped, and this typically involves evenly spaced vertical props that are relatively fast and easy to install, usually Acrow props.

- Lintel Fittings and Removals: A lintel is a beam that is placed above doors and windows to support the above load. Fitting and/or removing lintels can be difficult, but with a ‘strong boy’ specifically designed for this application, it is a very easy and efficient process.

- Pole Propping: Pole propping is needed when work is being carried out above, below, or near the pole, and it needs to be supported. Shore Hire has designed and developed our own custom power pole clamps for this application, and the system will generally involve multiple tilt bracing props at adjacent axis running to either a solid footing or temporary counterweight system to support the pole.

how are temporary props installed?

The majority of our temporary props can be installed by adjusting the length of the prop until it is slightly shorter than the desired height, standing the prop up and positioning it under the load to be supported, turning the adjusting nut or jack until the prop extends firmly under the load, and securing the foot and head of the prop.

All of our props can be installed by our customers, but installers should have sufficient training or instruction to properly install and use the props. Some of the innovative services we offer with our props are that our experienced engineers and project managers can talk our customers through how to install props, or our team of on-site riggers can handle the temporary works design and full installation and dismantling of the props.

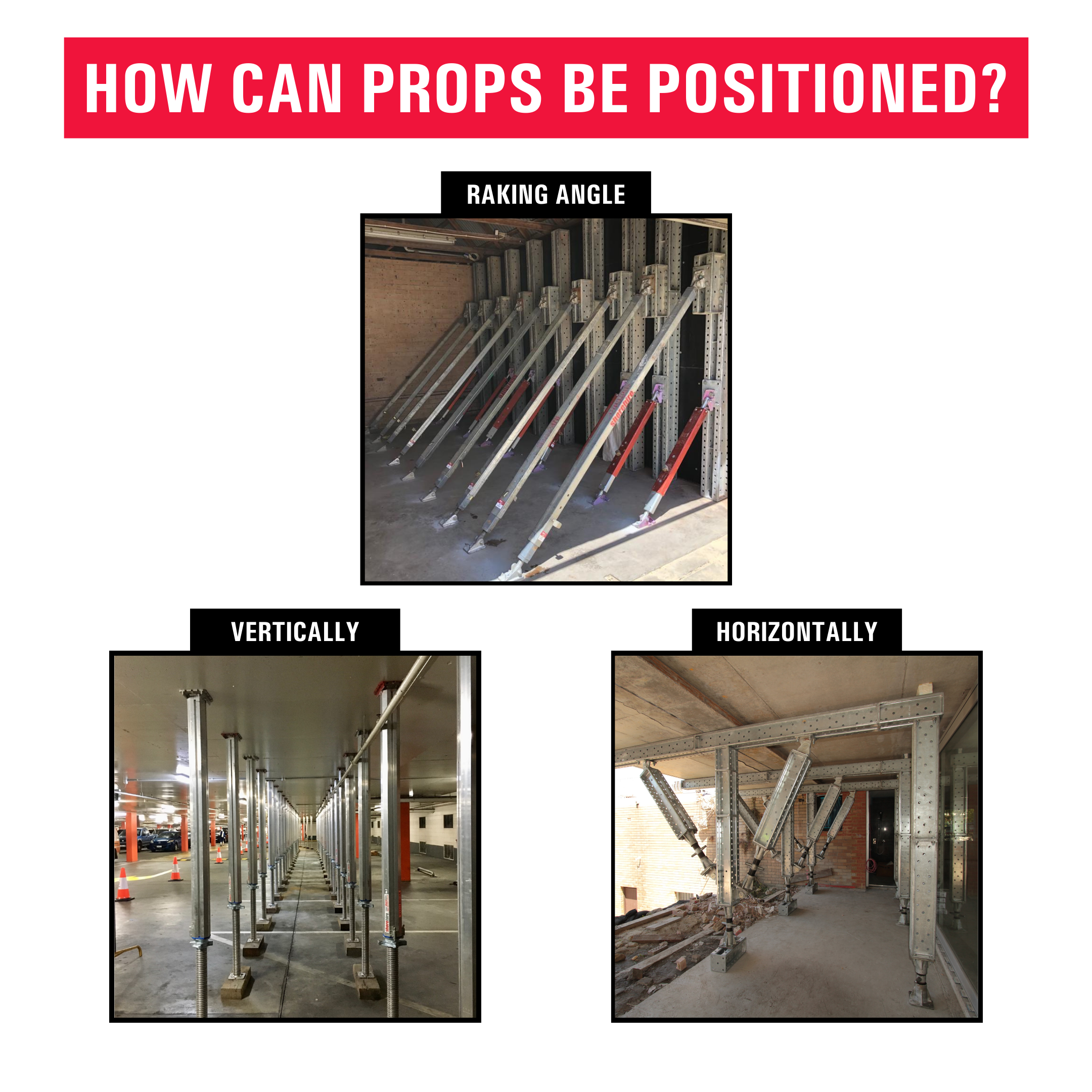

how can props be positioned?

There are three key ways that temporary props can be positioned to support the load of an existing structure, including:

- Vertically: Vertical positioning is the most common and strongest position for a prop. If a prop is being installed vertically, it’s important that they are completely straight or plumb to ensure they can support the load effectively. If they’re not, the load-bearing capacity of the props is reduced.

- Horizontally: Horizontal positioning is when props are installed laterally at a 180° angle. The main consideration when positioning props horizontally is shear loading. Horizontal positioning is also often used to simulate a beam application so that a load can be placed on top of the beam (or prop, in this case) and be safely supported.

- Raking: Raking is another word for angled – props that are positioned at an angle are typically used to support side walls or pre-cast panels. The ideal range for a rake is 45° – 60°, and anything other than these angles can affect the WLL, but only marginally. It’s also important to note that the most common height for a raking prop to be used on a wall is at two-thirds of the wall’s height, so if you’re propping a 3m wall placing the raking prop at 2m up the wall will be the typical best practice, but as always, please consult one our of expert team members before going ahead.

how many props are needed for a project?

Shore Hire’s team of engineers will be able to design what the temporary propping system will look like for your project, meaning that they will be able to tell you how many props you will need, at what heights and what the exact Working Load Limit (WLL) will be for the design.

However, there are also some basic factors that can help you determine the number of props you might need, including:

- The structure that the props are going to support, such as the type of structure (ceiling, building, masonry wall, etc.) and its height and length.

- The WLL of the props that are going to be used.

- The position the props are placed in (vertical, horizontal, or raked).

- If the props will be in a raking position, the angle at which the props are installed.

- Whether propping accessories like Strong Boys, Strong Backs, Engineered Blocks, and Needle Beams will be required.

Our dedicated team of engineers and technical sales representatives are experts in all our propping products, and are here to guide our customers throughout the entire sales process, from prop selection to design, and on-site review and sign-off. If you want to learn more, visit your nearest branch, email [email protected] or call our friendly team of experts at 1300 Shore Hire.